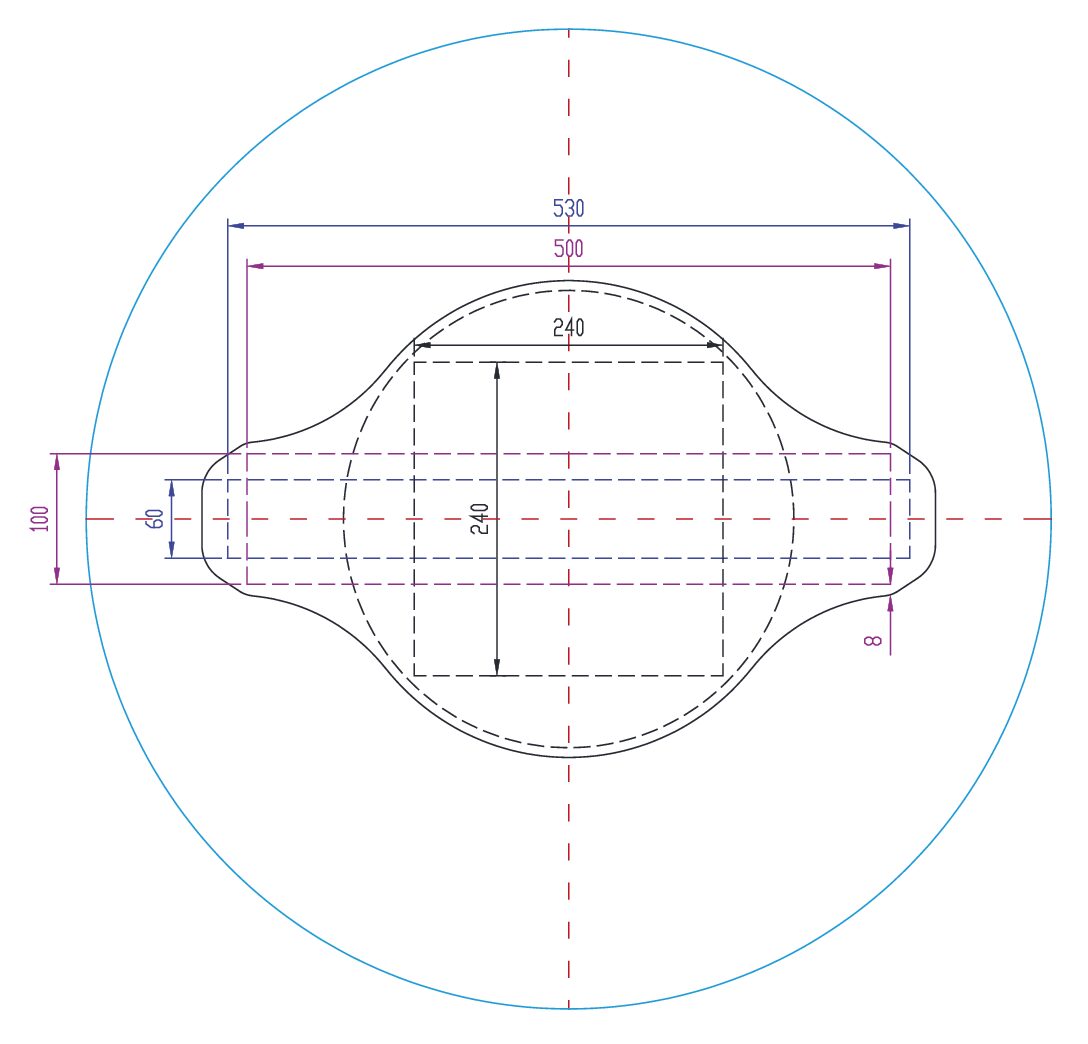

Drawing aluminium profiles

We specialize in supplying custom aluminum profiles to meet the individual requirements of our customers. Our aluminium profiles are the ideal choice for a wide range of applications, whether these are high-volume or smaller jobs. We offer different shapes, lengths and finishes of aluminium profiles to meet the most demanding needs. With an emphasis on quality, precision and speed of delivery, we strive to ensure that every customer receives a product that exactly matches their requirements and contributes to the success of their project. Thanks to our modern technology and expert team, we are able to implement even the most complex designs with maximum efficiency.

In addition to custom aluminum profiles, we also offer standard aluminum profiles in our e-shop.

Complete technical support

Preparation of all documents for production

Production of non-standard profiles to order

Sale of finished profiles on the e-shop

Custom production of aluminium profiles

We are able to produce virtually any aluminium profile to order. If you have specific requirements or doubts, please do not hesitate to contact us. We will be happy to help you and prepare everything you need.

Extrusion of aluminium profiles

Profiles with thermal break

Powder coating – a quality finish for your aluminium profile

Powder coating is a process that provides a highly durable and aesthetic surface for aluminium profiles. This process is carefully designed to ensure maximum quality and durability of the coating. Here is a detailed description of the workflow:

The profiles we supply are painted in accordance with the QUALICOAT, SEA-SIDE, QUALIDECO and QUALIMARINE certificates, which recognize and guarantee the entire process. We also supply painted sheets, which you can order on our e-shop ALUNET.cz.

We offer RAL, NCS, special, textured, metallic, wood decor and antibacterial colours.

Anodic oxidation – anodizing of aluminium profiles

Anodic oxidation, also known as anodizing, is an electrochemical process that increases the resistance of aluminium profiles to corrosion and mechanical wear. This process involves the formation of a thick oxide layer on the surface of the aluminium, which protects the material from the harsh environment and makes it ideal for applications in coastal areas and extreme climatic conditions.

The different colour and finish options also make it suitable for design applications. After cleaning the profile with acid and in an alkaline bath, the aluminium is immersed in an electrolytic solution where it serves as an anode. This creates a shiny, transparent layer of alumina (Al2O3) that is much higher quality than natural oxide. The colour shades are achieved by adding metal salts to the electrolyte. Finally, the surface is sealed in a deionized water bath at 100 °C.

We offer anodized aluminium profiles in many colours and surface finishes, guaranteeing European “EWAA-EURAS” quality in four classes, which differ in oxide thickness and application. In our ALUNET.cz shop you can find anodized profiles in various colours.

Types of standard aluminum profiles

In addition to drawing aluminium profiles to order, we also supply standard aluminium profiles – L profiles, U profiles, Steels, Flat bars, Round bars, Tubes, T profiles, C profiles.